What can mini-grid battery systems learn from utility-scale BESS projects?

Mini-grids are, as the name suggests, smaller than the typical power grid. Where most large-scale utilities consider demand in megawatts or gigawatts, mini-grids are typically considered on the scale of kilowatts (kW).

AMDA’s 2025 Benchmarking Mini-grids Report defined the average mini-grid generation size as 99kWp. In the roughly 10 years since Li-ion BESS have become cost competitive on a large scale, there have been vast improvements in nearly all aspects of those systems: energy density, price, product offerings, warranties and performance guarantees. Yet even larger mini-grids tend to have BESS installs that are typically in the 100s of kWh. For reference, most utility-scale BESS products are from 3,000 – 5,000 kWh (3 – 5 MWh) in each 20-foot enclosure, while BESS projects can range from 10 MWh on the small end to over 1,000 MWh (1 GWh) on the high end!

Although the size discrepancy is massive from MWh to kWh scale, the technology in most BESS products is nearly identical –nearly all these products are built on the Lithium Iron Phosphate (a.k.a. LFP or LiFePo4) cell (a type of Li-ion). So, what can the market trends of grid-scale storage teach us about mini-grids? This piece highlights 3 key trends in utility-scale storage and how they inform BESS costs for rural electrification.

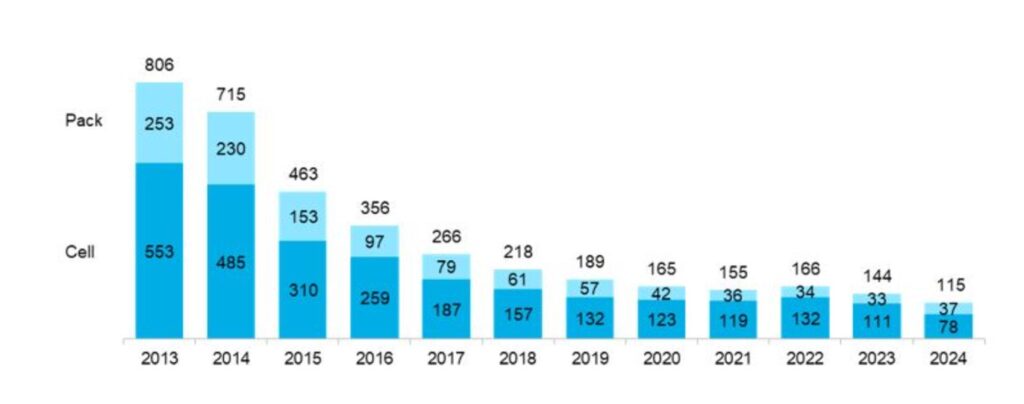

- Costs are falling fast. According to Bloomberg, Li-ion battery pack costs (typically 60-70% of a BESS project) fell a whopping 86% from $806 / kWh in 2013 to $115 / kWh in 2024.

Figure 1 Battery pack costs per kWh 2013-2024 (Source: BNEF)

Although MWh-scale products tend to benefit from lower costs more directly than kWh-scale ones, cost decreases have been seen across the market, making energy storage an increasingly affordable part of mini-grids. According to the AMDA Report, PV+BESS generation costs range from $3,000 – $4,500 / kW, compared to diesel hybrid systems, at $1,500-$2,500 / kW. Lower BESS OpEx costs have made them cost-competitive on a per-kWh basis, which will become even more pronounced as costs continue to fall (battery pack costs in China are already below $70 / kWh!).

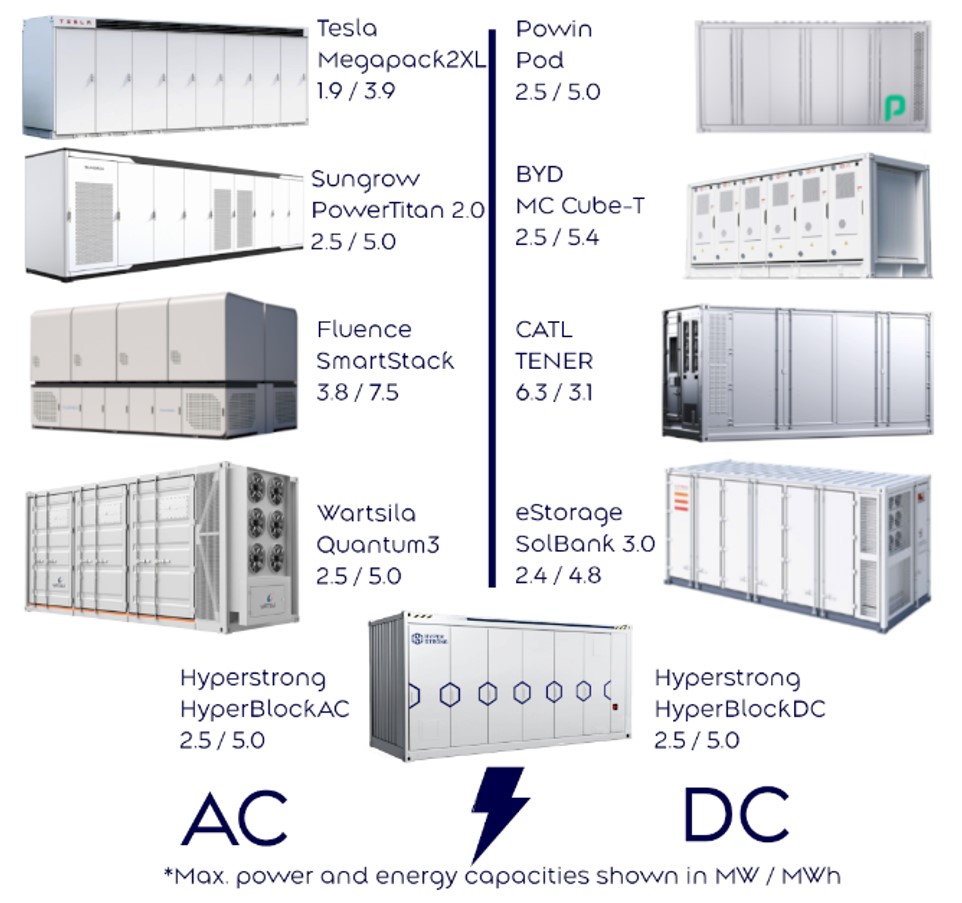

- The rise of the AC Block: Utility-scale BESS products come in two different configurations. The DC block has DC terminals, typically at high voltages (maximum 1500 VDC), and an external bi-directional inverter (or PCS) providing 3-phase AC power. An AC-block product, by contrast, has an integral inverter, outputting AC power directly from the BESS terminals (typically at 480 – 800VAC). The AC-block product is more expensive, but provides simplicity: fewer components to wire on site, a warranty and guarantee which cover the battery and the inverter, and they tend to have a simpler controls system, relative to DC Block. While higher CapEx is always a challenge for any projects, these benefits are well-suited to mini-grids where lower cost and complications of maintenance are critical to long-term reliability. kWh-scale battery product innovations have brought many new AC- and DC-block products to the market.

Figure 2 AC vs. DC Block Products

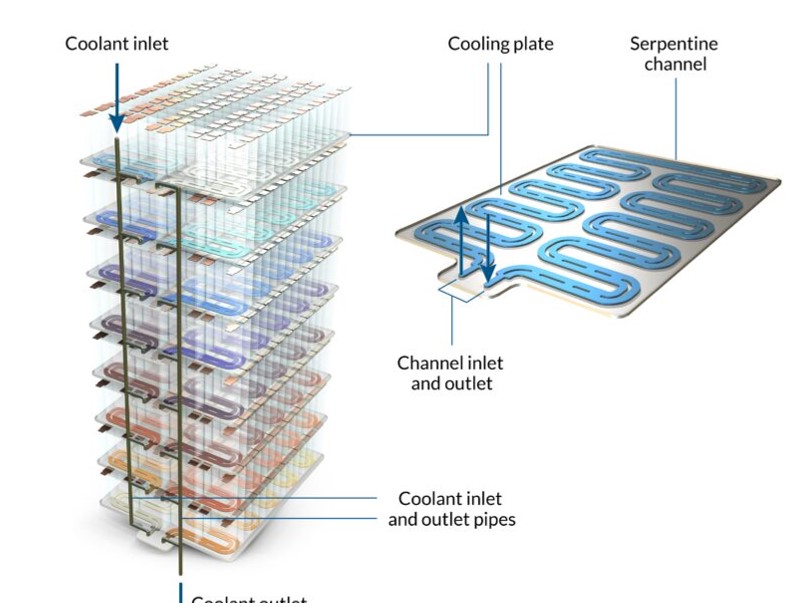

- Liquid cooling for the win: In 2020, there was still a debate around whether liquid- or air-cooled BESS products would dominate the marketplace. By 2025, the debate is over – liquid cooling has proven to be the superior technology for cooling batteries, with nearly every utility-scale product transitioning to this technology. Sadly, this is a trend where kWh-scale products have been slow to keep up, with still many smaller BESS products coming with air-cooling (or in some cases no cooling at all!) Given the extremely hot environments where most mini-grids are built, this is a major disadvantage for projects, decreasing their lifespan (often at a much lower CapEx). Utility-scale BESS products typically come with a 20-year, 7,200-cycle warranty, largely driven by their robust cooling systems, which aim to prevent battery cells from exceeding 25˚C, even when outdoor conditions rise to 45˚C. Although kWh-scale products get much shorter warranties, it is strongly recommended to use a liquid-cooled BESS product wherever possible.

Figure 3: Typical liquid-cooling system (Source: Renewable Energy World)

These trends provide just a glimpse into the rapidly evolving world of energy storage technology. As battery tech continues to improve, we hope the trends from MWh-scale storage products trickle down to kWh-scale, allowing for more reliable, cost-effective, and lower-carbon solutions across the mini-grid sector.

About the Author: Drew Lebowitz, P.E., is a US-based electrical engineer and the Managing Director of ARE Member PowerSwitch, an energy storage advisory firm. He has advised on BESS and mini-grid projects in Panama, Haiti, Zambia, Kenya, Tanzania, and Senegal, and currently works in both these sectors. He is the author of The BESS Book: A Cell to Grid Guide to Utility-scale Energy Storage. Use Code ARE25 to get $10 off a physical or digital copy of the book at thebessbook.com through September 30, 2025. PowerSwitch provides reduced-rate advisory services for Energy Access projects and firms working in the rural electrification sector.